ELECTROCOAGULATION

INTERECO is introducing a new technology Electrocoagulation to remove as sludge both heavy metals and most organic compounds.

It is, at last, the industrial realization of the laboratory theory consisting of having a current pass through wastewater to make the suspended solids and most dissolved salts react as normal flocculated sludge.

INTERECO’s system works with the passage of current (with the only eventual correction of the pH values to guarantee a good conductivity), requiring practically no chemicals. With this new technology, INTERECO is able to easily solve problems which are difficult or even impossible to solve with traditional systems. By not requiring chemicals, even with simple waste streams, running costs and installation are economically friendly compared with traditional systems (biological – physical – chemical). It is also very simple to upgrade or renovate existing plants because of the much smaller required space.

In addition to operating on several different kinds of wastewater, with the use of the Electrocoagulation System INTERECO is now able to remediate, with very good results, contaminated ground waters.

Another very interesting application INTERECO is working on, is the use of electrocoagulation to reduce concentrates of Reverse Osmosis systems (especially while treating industrial waste water), to realize in most cases an almost complete recycling of the water and reaching of the so-called “zero discharge”. Here the running and installation costs are much lower when compared with those of evaporation systems.

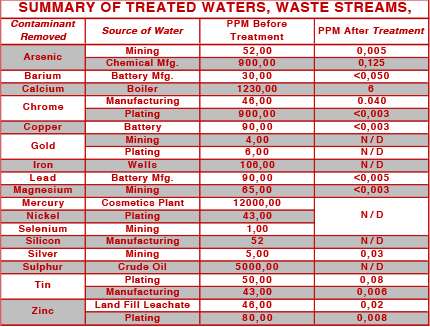

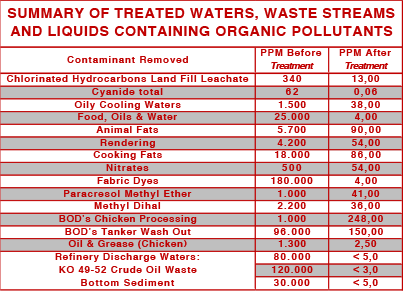

The amazing results achieved in reducing pollutants can be seen in the following tables.

Properties and plus of electrocoagulation:

- Wide number of pollutants removed (both organic and inorganic)

- Minimum, or no, pH adjustment required

- Pollutants removal high efficiency

- Formed flocs are stable and settle easily

- Reduction, or total removal, of bad odours (thanks to sulphides oxidation)

- Pathogens removal (E-coli <1/100 ml)

- Heavy metals removal

- Capacity to work even under sudden chemical concentration increases (even reaching the very high levels which would make a traditional plant not work).

- Nitrogen transformed in Nitrites and Nitrates instead of Ammonia.

- Low running and maintenance costs

- Reasonable installation costs

- Limited required area for plant installation

- Easy capacity increase of existing plants